Pool cues come in a large variety of designs, styles, and price points. From inexpensive, mass produced cues to one-of-a-kind custom cues that can cost thousands of dollars. The large disparity in price comes from the materials used and how the pool cue was constructed.

Cues with elaborate designs and relatively low prices likely have a solid maple core with a decal (fancy sticker) over the top. The real works-of-art, though, are the pool cues that have real points and inlays built in. Making a custom pool cue with those sorts of traditional adornments takes a ton of skill, the right equipment, and years of experience. In this article, we will explain some of the most popular cue construction methods and what they mean to the pool player.

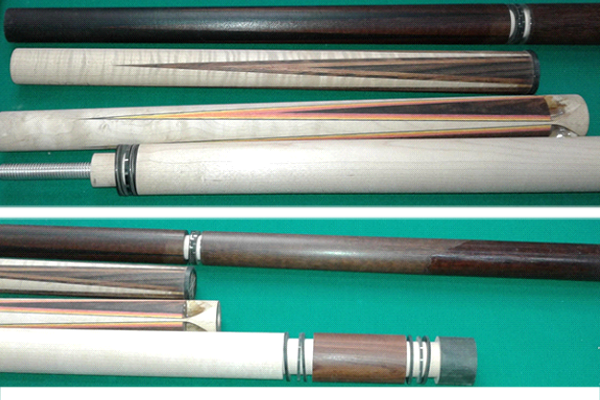

There are really four categories of how pool cues points are constructed. Full Splice, Half Splice, Inlaid or decal. These four methods have been around for a long time and represent the entire spectrum of cue building.

Full Spliced Pool Cues

Let’s start with Full Spliced cues. A full splice cue (as shown in the images) means that the points are milled at both ends and interlock with one another. The term FULL Splice means that the bottom portion of the point is one piece that extends to the length of the handle of the cue. This process is often seen in high-end custom cues and house cues. It is a very stable and strong construction method that requires special milling equipment and is not widely practiced. In fact, there are only a handful of cue makers out there that still use this method due to its costly and time consuming production process. That being said, you can bet that most full splice cues are expensive.

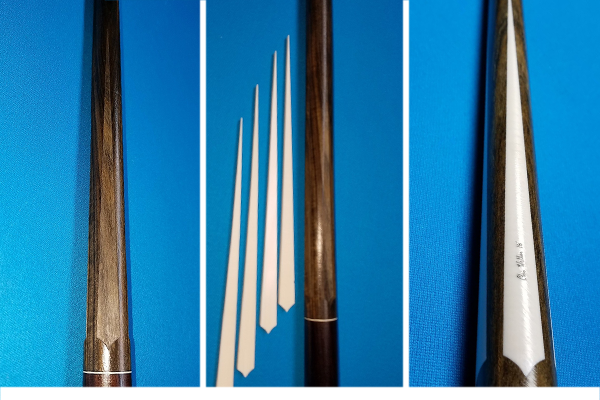

Half Spliced Pool Cues

Half Splice cues are probably the most popular method among cue makers. As you can see in the pictures/videos below, the forearm of the cue is milled into pockets where the veneer points are then placed into the mill pocket in a V shape. These are then glued together and turned round on a lathe. Half splice means that the splice stops at the A Joint (where the forearm and handle are joined together). This method is much less expensive, but still requires special equipment to be executed properly. Custom cue makers prefer this method for its stability and it allows them to get those long sharp lines at the tip of the point.

To show the half splice pool cue contruction process, I went and saw my buddy, Mike Durbin at Durbin Custom Cues. We made these step-by-step videos and pictures to help show you all how it's done!

The cue making process often starts with coring. A lot of custom cues are made with exotic or decretive woods and sometimes these woods can be extra heavy. Because it is important for a pool cue to be well balanced, coring that heavy wood will allow for the cue maker to control the weight and still hit the ideal balance point. It also provides an extra bit of stability to keep the cue from warping over time. This is done by clamping down the exotic wood dowel and using a tool called a “gun drill” (shown below) to get a perfect hole through the center.

Once this is done, the cue is ready for the milling process that involves cutting out the groves that will be fit with the veneers and points.

Veneers are those multi-colored pieces that outline the main points. They start as flat layers of stained wood that are glued together and then cut, as you can see in this video.

After the veneers are cut and the wood is milled out the pieces are ready to be glued into place and wrapped up tight until the glue dries.

Now it’s time to turn down the points into one smooth piece. This must be done very carefully to avoid breaking any of the pieces.

We now have a half spliced forearm that is ready to be assembled with the grip area, decretive joint rings, and sleeve.

The parts of the butt are assembled with dowel joints, metal bolts, and glue. The sections often feature decorative rings where the pieces come together. The pool cue gets finished off with some final touch-ups and is then lacquered and wrapped to complete the process.

Why buy a spliced pool cue?

Why splice the points you might ask? Well, when the points are spliced into the cue they are structurally a part of the build. This means that a cue made by the same cue maker that has spliced points will hit different and be more stable and stronger than a cue without points at all.

Pool Cues with Inlays

Inlaid points are a long tradition with some cue makers. They require special equipment, such as CNC pantagraphs, to cut the intricate inlays and corresponding pockets to inlay them into. Inlaid points are not structurally part of the build but are just as gorgeous when executed by an expert cue maker. Inlaid points can give you so many options (as seen in the photos) for design over spliced points. Not only does it take an artist to design them, but you also need to be an expert at figuring out how to make the pieces and how to put the puzzle together. Many custom pool cues have half splice points AND inlays.

Decal Pool Cues

The final style of cue points is the Decal Point. The decal point is just what it sounds like. A decal is precisely affixed to the cue underneath the finish. This is an economical choice by some cue makers or brands to offer exotic and intricate designs and still keep the selling prices down to a reasonable amount. These points are by no means structural and are clearly for ornamentation only, but it allows any budget to have a beautiful looking and great playing cue.

How Pool Cues are Made: Full Video

- RELATED ARTICLES

- How to Buy the Right Pool Cue – By Florian "Venom" Kohler

- Should I Use a Low Deflection (Squirt) Shaft? – By Tom Simpson

- Pool Cue Buying Guide – By PoolDawg Staff